The Ultrasonic Anilox Cleaning Process

How does the cleaning process work?

Cleaning is a two-step process. The first step is a thorough soaking of the roll to soften the buildup of hardened inks and resins contained in the anilox roll cells. The resins are the most difficult to soften because they dry very hard and clear. Many times operators will think that the roll is clean because they cannot see anything in the cells, but they may in fact still be plugged. Rolls that have not been in use and have sat on shelves for months, or years, will take longer to soak than rolls that are used daily as the resins will be drier and harder to soften.

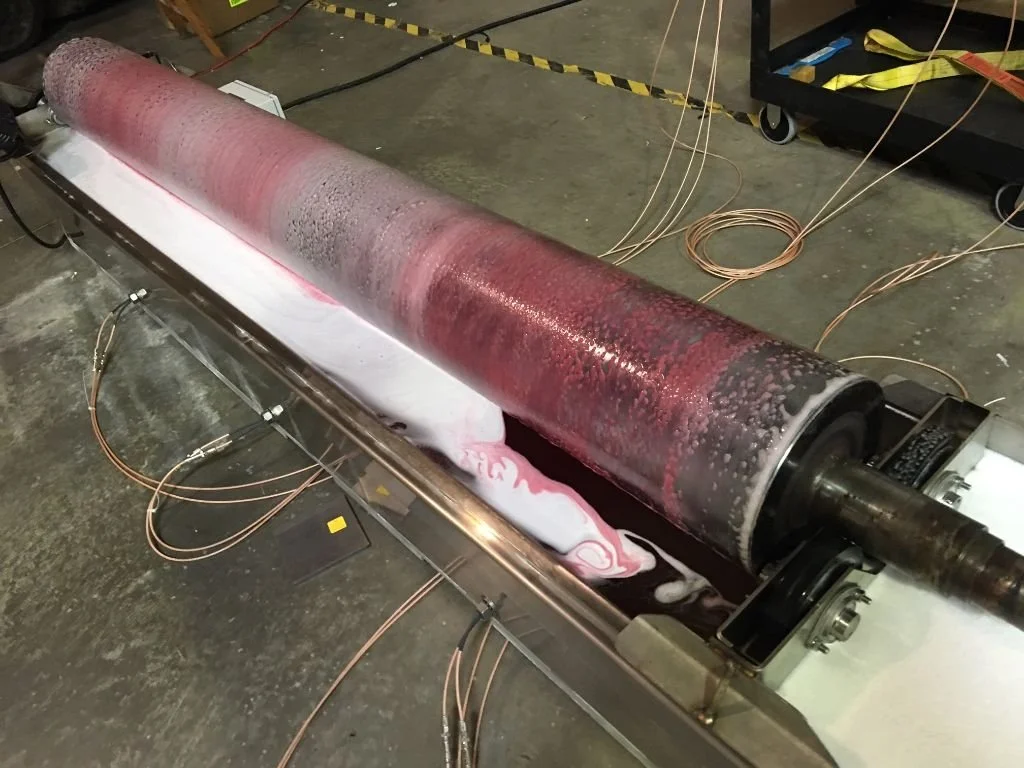

The second step is a brief application of ultrasonics. This should be limited to no more than 5 minutes at a time. If you turn on the ultrasonics and do not see an immediate camouflaging taking place on the roll, then the roll has not been soaked long enough. Go back to the first step and soak the roll some more. If the camouflaging is taking place, you can speed up the process by scrubbing the roll with the rubber block that is provided. After the camouflaging has cleared away, remove the roll from the system, rinse the roll, and then you can place it back in production.

How long will the cleaning process take?

The cleaning process will vary with many factors including:

Has the roll ever been cleaned before?

How dirty is the roll?

When was the roll last used?

When was the roll last cleaned?

For first-time cleanings, expect the cleaning time to last at least one hour. For subsequent cleanings, the cleaning time should be reduced to 10 to 15 minutes. These stated times will vary depending upon the factors identified above.

How do ultrasonic cleaning processes differ from blasting processes?

In its simplest terms, the two processes can be compared to those of a vacuum cleaner and a sand blaster. Ultrasonics use a sound-wave technology that creates air bubbles in the cleaning solution that will form within the anilox roll cells. The ultrasonics will then implode or collapse the air bubbles, which in effect pulls the debris and contents of the cells from the roll. It is in effect a vacuuming process. The blasting processes are similar to sand blasting. The process shoots a medium (typically fine granular plastic or baking soda) at the roll under a very high rate of pressure. The force of the medium hitting the dried on inks and resins then chips away at the unwanted debris.